LONG TRADITIONS IN MANUFACTURING OF PLASTIC AND STEEL WIRE PRODUCTS IN FINLAND

Roots of the Company

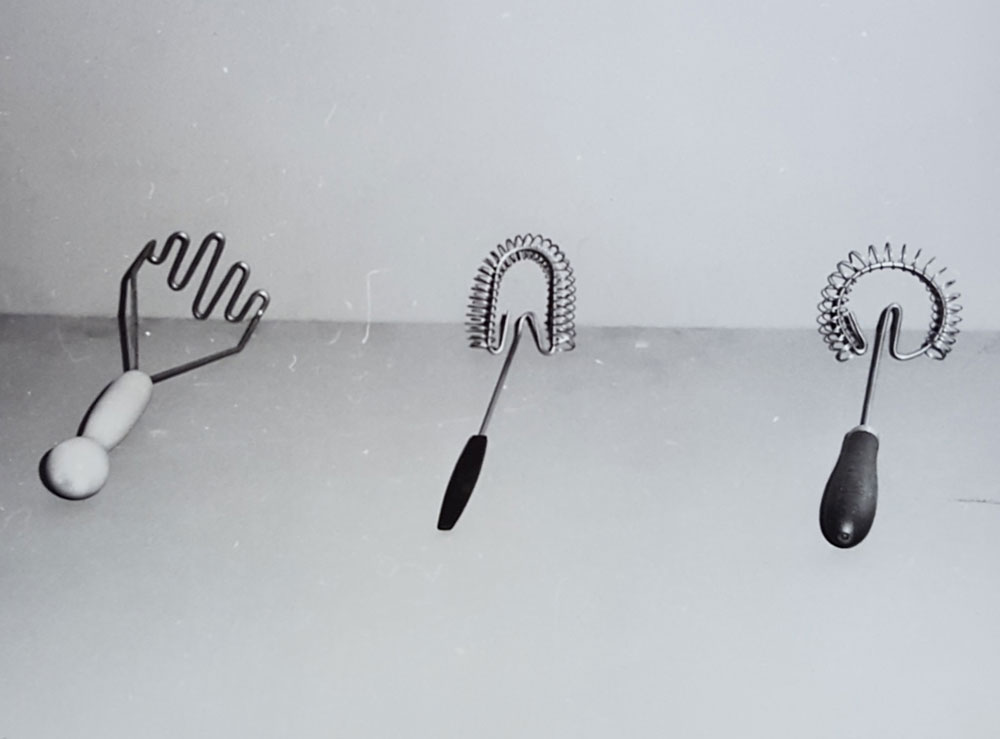

The Roots of company can be traced in the yearly 1950s. Brothers Eino and Heikki founded with their father Yrjö the Pohjanlehto import and wholesale business which started under the name Lypo. The offices of the business were at that time in Pori, within a sauna chamber in Vanhakoivisto. Own production was planned gradually, and the first developed product was a cooking whisk. A new company was established for this purpose in 1955, Lanka and Muovi Ky, and a small workshop was built in Niittymaa, Pori.

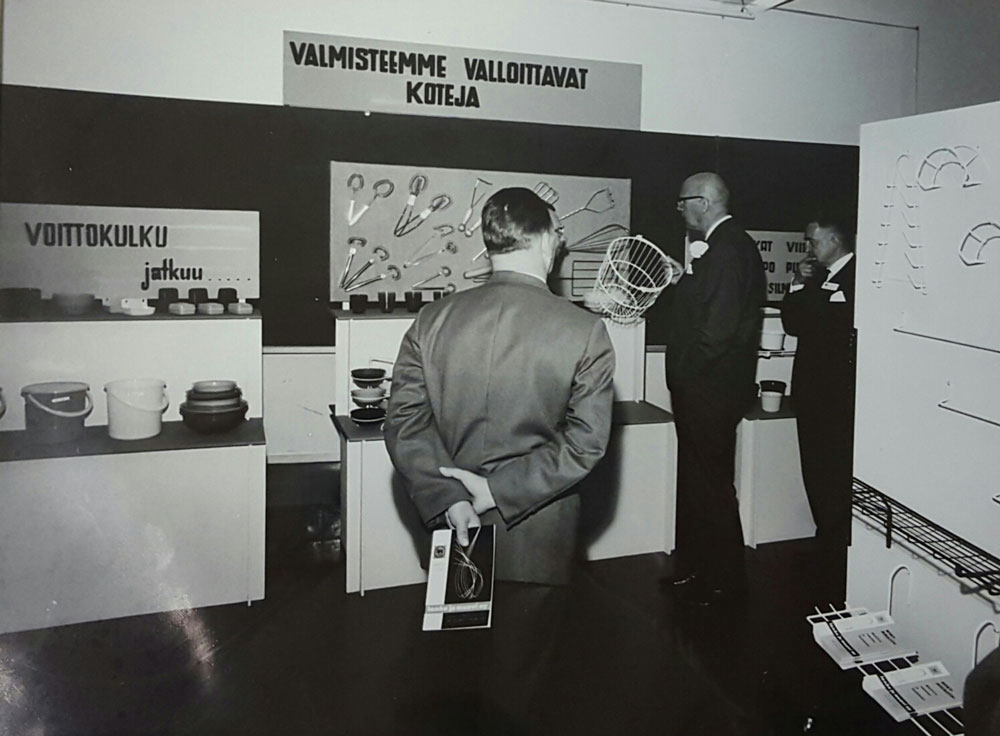

When developing new products, the problem became surface coating treatment of products. Since the necessary technology was not available in Finland, Eino Pohjanlehto set out to find the solution abroad. A solution to the problem was discovered between late 1956 and early 1957, when Eino found in Italy a company manufacturing polyethylene raw-material. He received a small sample of the raw-material from this manufacturer; surface coating experiments were made in Pori, in the regular kitchen oven of the Kiertokatu apartment. The successful experiment in surface coating led into significant investment, and we were the first company in Finland to introduce the polyethylene coating of metal. This insight launched the strong growth of the business. Product portfolio quickly expanded to cover all household storage needs.

In the early 1960s, a new interest in household plastic products led to new investments. Plastics gradually grew into an important product family, and the company became one of the market leaders in household plastics in Finland. By the end of 1960s, 80% of the business turnover originated from the manufacturing of plastics products.

The Oil Crisis Changes Everything

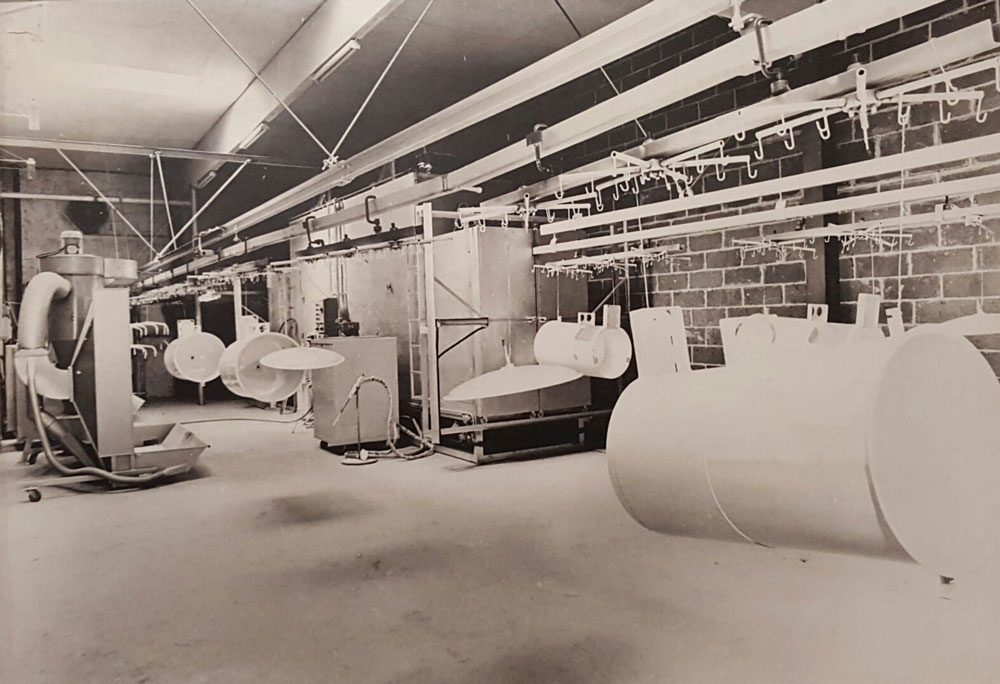

Early 1970s was the start of a world-wide oil crisis which lead in to a huge price hike of plastic raw-materials. This in turn lead into unhealthy competition, and started hard price competition among the industry’s businesses. At about this time, Rosenlew, the refrigerator manufacturer located in Pori, made a major export deal. At the time, Rosenlew manufactured their own steel wire shelves. However, Rosenlew wanted to give up the production of steel wire products, and discovered us. A new partnership agreement changed the direction of the entire company, and the product portfolio started again to develop more strongly into steel wire products. Extensive investments in manufacturing technology were made, and gradually steel wire works became a significant business. The main portion of production consisted of sub-contracting in various industries, but at the same time we continued manufacturing, selling, and marking our own storage products.

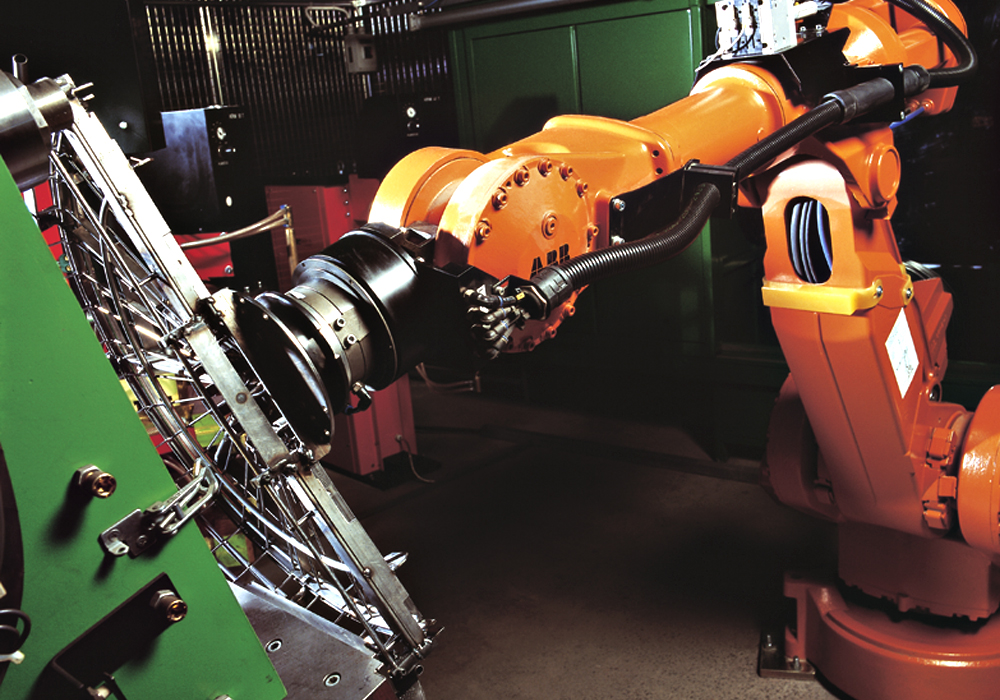

Technology changes the Industry

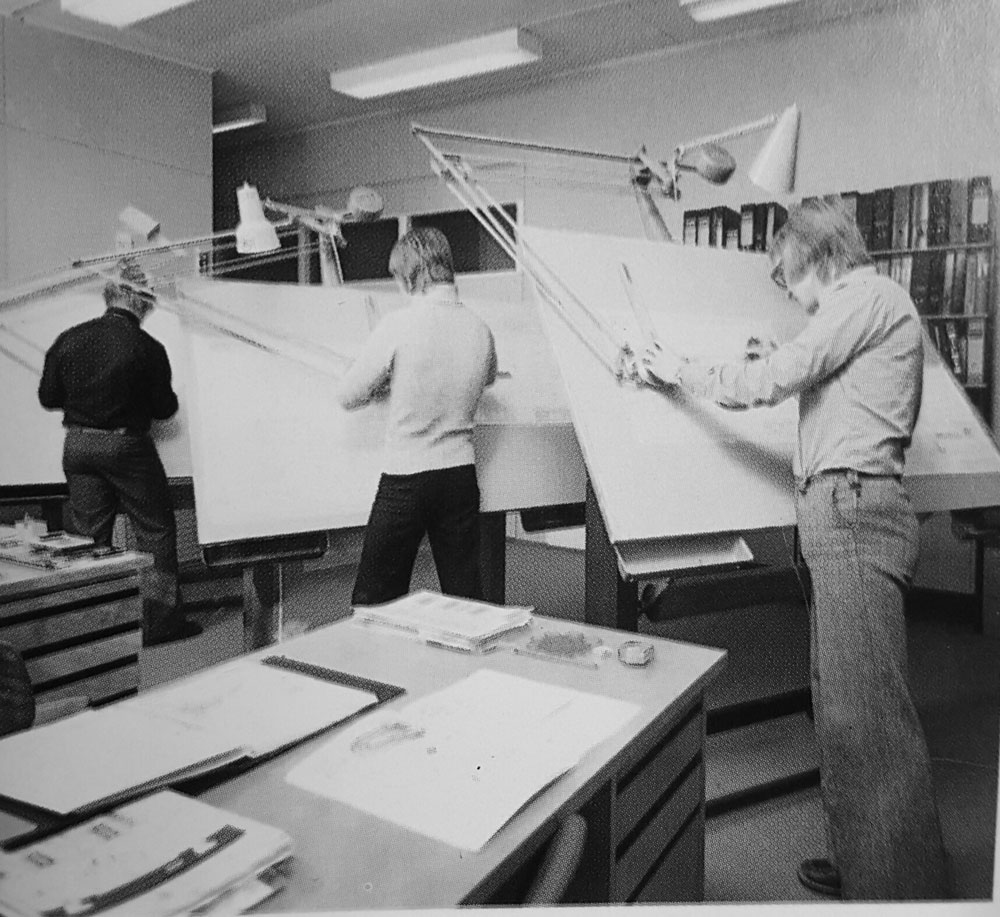

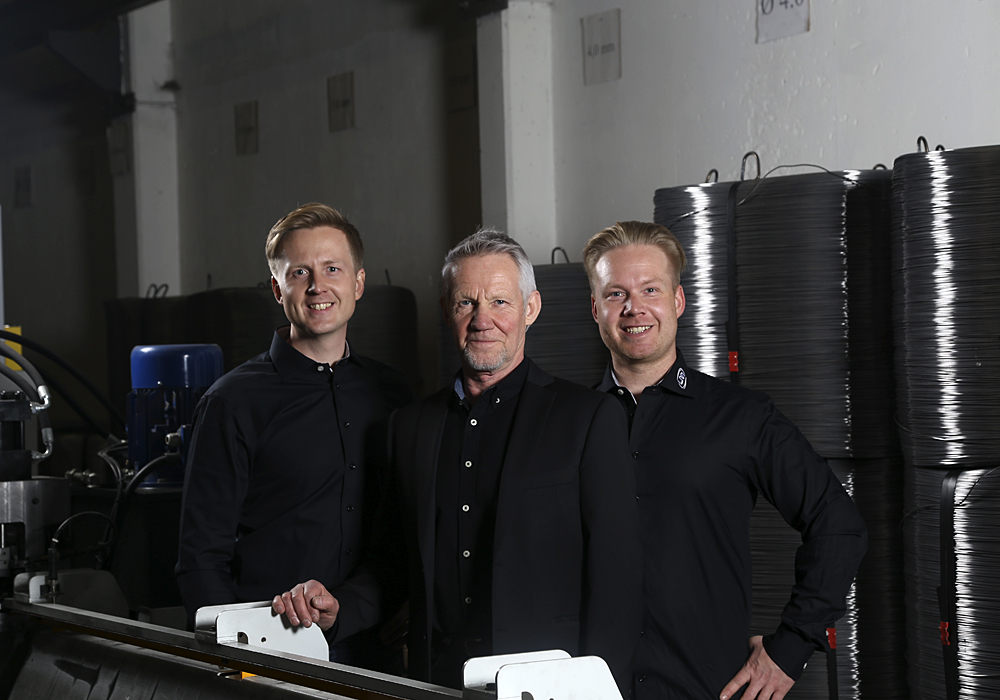

Manufacturing of steel wire product was very labour intensive, and even in 1970s, the company had 150 employees. At the same time, new technology was introduced in the market, and we started to develop new working methods. In 1986, the first robots appeared to help with lifting heavy pieces, and the company employed 120 employees even at the end of 1980s. The cornerstones of the company consisted of high quality and the adjustment of production according to the customers in different industries. At the end of 1980s, the lead of the family business was taken over by Eino’s son, Harri Pohjanlehto.

Collapse and new Rise

The recession of the 1990s had big effect on the company’s operation. Due to the recession, sales dropped rapidly, and this lead in to cutbacks in the workforce. During the recession, the corporate form of the company was changed into limited company, and the same time investments were made in new technology and working methods. The successful investments in previous years, skilled personnel, and a great product portfolio propelled the company into new growth, when the time of reconstruction began in Finland. The strong growth carried all the way until the year 2008.

Situation today

Today, our company is among the leading manufacturers of plastic coated steel wire products in the Nordic countries. Our clients include mainly hardware stores, supermarkets, plastics industry specialist stores, internal decoration stores, and various industries, e.g. kitchen furnishing, furniture, cold storage, and metal and electronics industries. In the international markets, our most important clients are in the Nordic and Baltic countries.

During the early years of the company, almost all the machines, equipment, and working methods had to be developed by yourself. Even now, our own design carries a decisive part in the machine investments we make. Manufacturing of products happens now in highly automated production lines, and IT systems are used to help with operations. Our facilities are still located in Pori Niittymaa, and they consist of an factory unit of approximately 11,000 square meters. The company is lead by the third generation of the family, Harri's sons Aki and Pasi Pohjanlehto.

The basic concept of our operation still includes high quality products and high customer satisfaction. We guarantee to our client products with appropriate quality and price even in the future, by setting high demands on quality of raw-materials, practicing constant product development, by investing in personnel skills, and by investing in new technology.

Check out our current production sites for the following links:

Manufacturing of steel wire products-

Powder coating-

Manufacturing of plastic products-