Electrostatic powder coating and LD polyethylene coating of metal

Powder coating of metal products and LD polyethylene coating with over 60 years of experience in quality and reliable subcontracting. Ask for a quote!

We offer our 60 years of experience in subcontracted powder coating service to businesses. Powder coating and LD polyethylene coating are an important part of our production process. Our long experience, the latest powder coating technologies in the market, and correctly chosen raw materials ensure the best possible result to your metal products.

Electrostatic powder coating – for hard and durable coating

Powder coating is well suited for thin metal products which require shock-proof and durable coating. Powder coating is environmentally friendly, as it uses no solvents. Powder coating is suitable for various uses, and the type of powder is selected according to the intended use. Epoxy powders are suited for uses which require good chemical durability. Epoxy polyester is suited for uses requiring hard-wearing surface. Whereas polyester is suited for outdoor use as it can endure UV radiation best. In uses requiring special corrosion endurance, the piece is electro galvanized or hot-dip galvanized with zinc before the powder coating. Combi Coat coating gives a product good corrosion durability. Food-grade approval is available for most powder coatings.

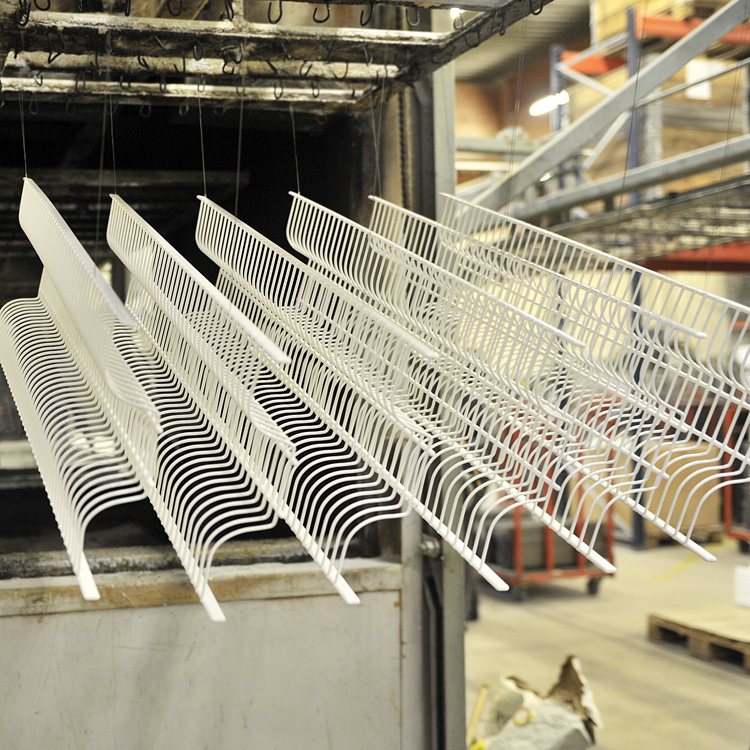

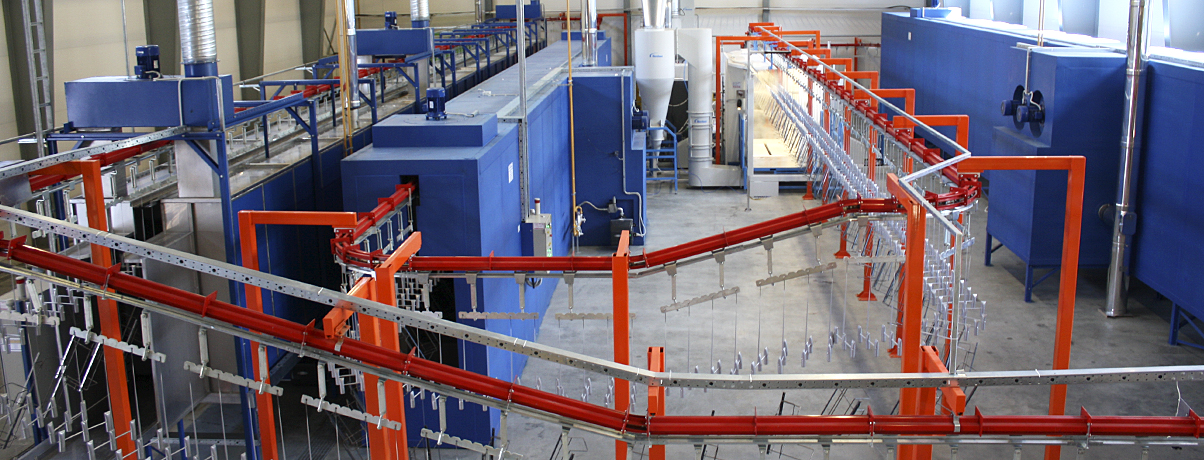

We powder coat steel wire, thin-wall pipe and sheet metal components, and comprehensive metal product assemblies cost-efficiently with our 170 meters long continuously operating automatic paint line. The finished paint result is ensured by a 5-phase washer line in which nano-ceramics can be used for pre-treating the surface.

The painting line is based on continuously working hanging conveyor which moves the work piece automatically from one process to the next: hanging up on the track -> pre-treatment -> drying -> powdering -> curing oven -> unloading from the conveyor. The painted piece is first brought for pre-treatment in a 5-phase washer tunnel in which it is cleaned up of any dirt and oil. Washing phases: alkaline washing, rinsing with tap water, rinsing with de-ionized water, conversion/nano-ceramics treatment, rinsing with de-ionized water. After the wash tunnel, the piece is dried in a drying tunnel, after which it is pre-treated for painting. Powdering takes place by spraying plastic powder using static electricity on the surface of the work piece with six automatic sprayers. After the automatic painting, a painter makes manually any necessary correction painting on difficult surfaces. After painting, the piece continues to the curing oven in which the powder melts and forms a shock-proof paint film. After this, the painted piece is finished, and it is removed from the conveyor. If necessary, any marks on the hanging spot are then spot painted.

The painted piece must be maintained a certain time in a certain temperature during the process. The high quality of the painted surface is directly dependant on the qualities of the powder type, and these must be strictly followed.

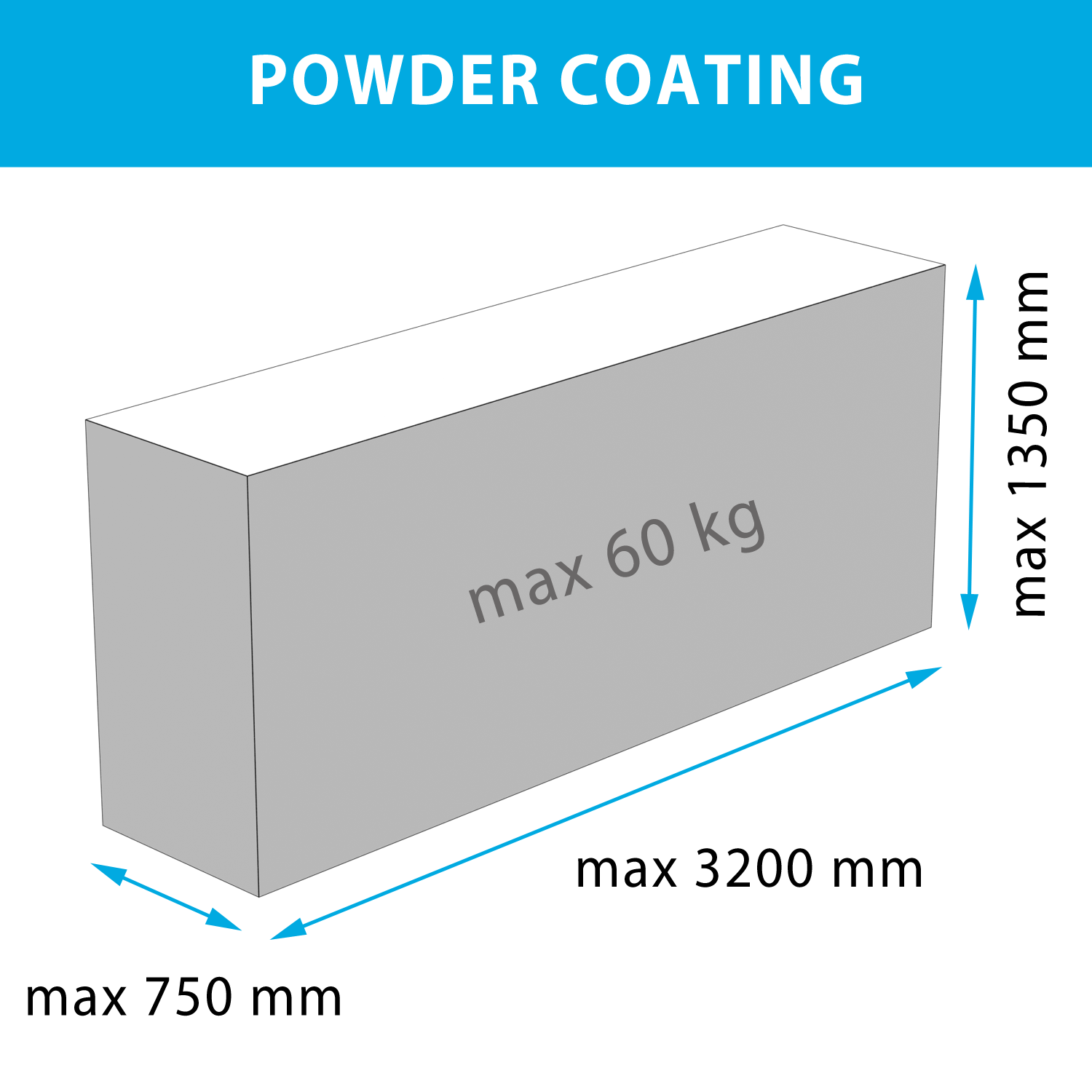

GOOD TO KNOW:

Thickness of the coating: typically, 0,05 mm to 0,1 mm (varies by powder type).

Size of the painted piece: maximum dimensions width 0,75 m x height 1,35 m x depth 3,2 m.

Weight of the painted piece: maximum 60 kg.

Colour: Please ask availability by specific RAL colour code.

LD polyethylene coating – for corrosion proof and flexible coating

A LD polyethylene coated metal piece is regarded as plasticized coating due to the durable and flexible coating. The coating is smooth, soft, and covers well any welded joins. The coating feels silky soft and high quality by touch thanks to the high coating strength. The polyethylene coating is well suited for indoor metal components which require flexible, elastic, and corrosion proof coating. Typical applications include kitchen dish draining cabinet wire shelves, and wire baskets and shelves in freezer cabinets. LD polyethylene powders are environmentally friendly, and products manufactured with this coating method have food-grade approval. The LD polyethylene coating endures poorly mechanical abrasion and impacts, unlike epoxy polyester which is excellent for such use.

We coat steel wire, thin-wall pipe and sheet metal pieces with LD polyethylene on our continuous automatic painting line. The special feature of this coating material is that the painted piece is not pre-washed.

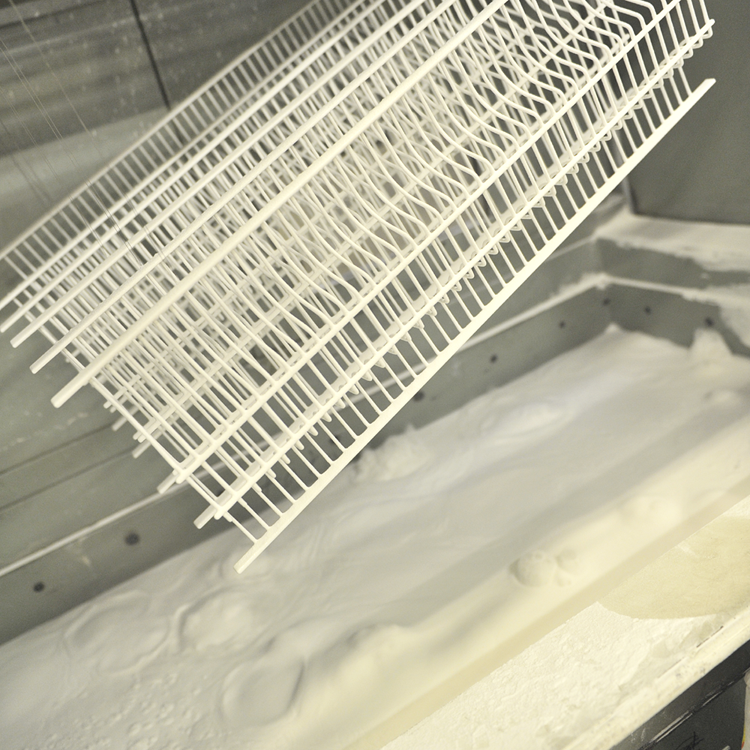

The painting line is based on continuously working hanging conveyor which moves the work piece from one process to the next: hanging up on the track -> pre-heating -> powdering -> curing oven -> unloading from the conveyor. The painted piece is tied up with hanging wires, and it is hung on the conveyor. The piece is first moved into a pre-heating oven with a temperature of approximately 400°C. After this, the conveyor moves on to the powdering phase in which the work piece is sunk in the fluidised powder bed. After powdering, the piece continues to the curing oven heated to approximately 200°C in which the powder melts and forms smooth coat. After this, the piece is detached from the hanging conveyor, and the hanging wires are manually cut off.

Due to the thicker coat, the manual work for attaching the hanging wires, and the slower total process, LD polyethylene coating is more expensive than electrostatic epoxy or epoxy-polyester powder coating.

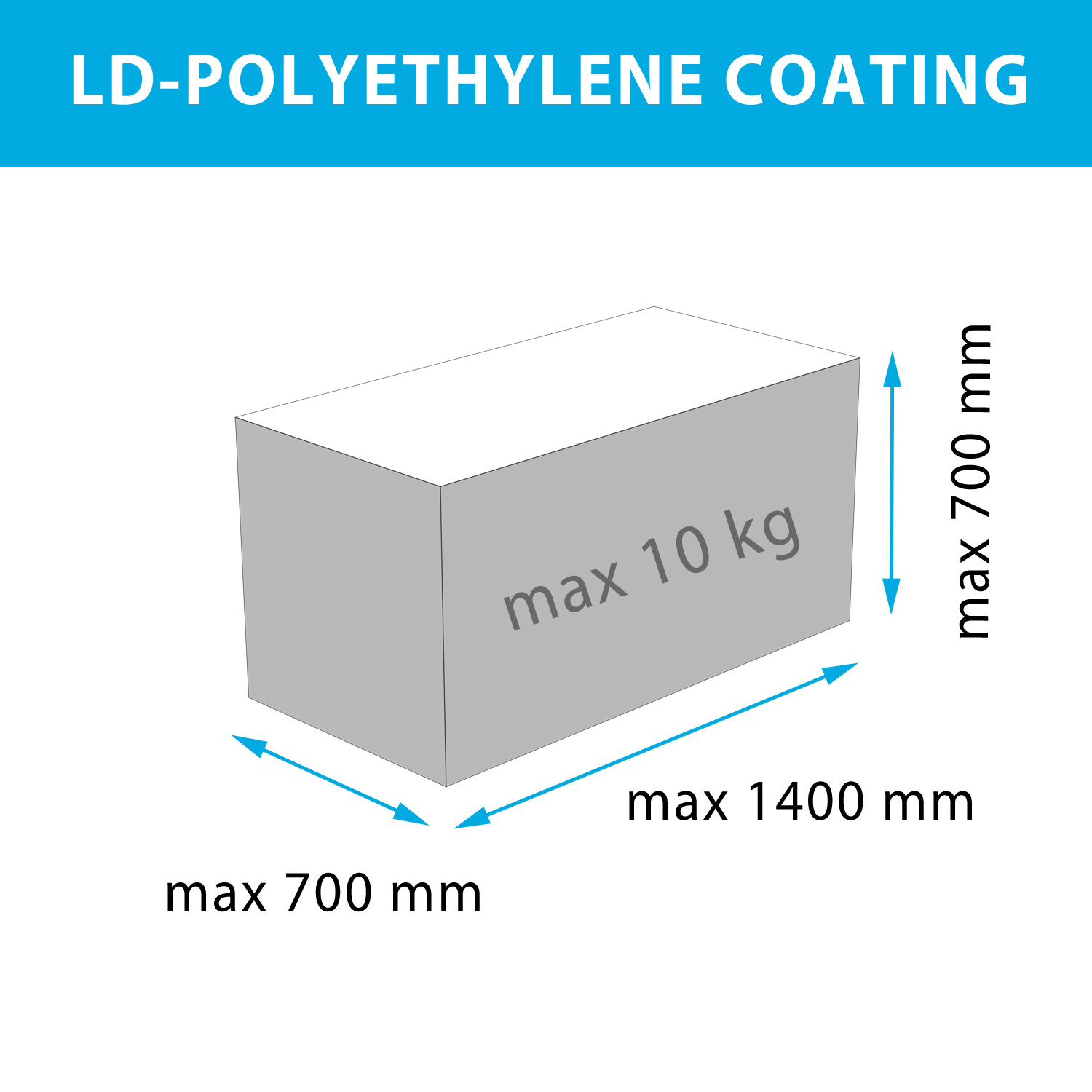

GOOD TO KNOW:

Thickness of the coating: typically, 0,5 mm to 1 mm (varies by case).

Size of the painted piece: maximum dimensions width 0,7 m x height 0,7 m x depth 1,4 m.

Weight of the painted piece: maximum 10 kg.

Colour: Anthracite grey silver (pearl effect) or white.

Hanging spot and mark

The piece to be powder coated must contain a point from which it is hung on the conveyor. It is often easy to locate such point in a steel wire product, but a sheet metal piece requires in many cases a special hole for hanging. We recommend the location of hanging in a point which does not endanger the functionality of the product and is not aesthetically unpleasing. The hanging point is very small, and it is spot painted for electrostatic powder coated pieces if necessary. The hanging point is selected with the client before coating. Almost unnoticeable spot from the hanging wire is left on LD polyethylene coated pieces.

Quality assurance

With electrostatic powder coated pieces, the paint quality is first inspected visually, considering the smoothness of the surface and sufficient spreading of the paint over the agreed surfaces. After this, the thickness of the paint film is measured, and the paint’s durability is tested mechanically. Surface quality is tested by bending the piece; the finish should not break or crack, but stretch. Impact durability is tested by sharply hitting with a hammer at the powder coated product’s surface, and it should endure the impact without breaking/cracking.

The quality of an LD polyethylene coated piece is first inspected visually with special attention to surface smoothness. After this, the hanging points are checked for careful finish (no sharp wires). The LD polyethylene coated product is very flexible and corrosion-proof, but doesn’t handle mechanical abrasion or sharp impacts.

Markings and packaging

Powder coated pieces can be marked with customer-specific stickers or product labels. Finished products can be packed in cardboard packages or piled up on EUR 1 or EUR 2 sized pallets. A cardboard piece or plastic cover is placed between layers, depending on each case. Pallet or packages sizes and markings are agreed on with the client, and the details are added to the work instructions. The packaging needs to be protected and firmly attached for transport, and the contents must be well marked. A finished packaging shall always be accompanied with slip which shows manufacturing date, batch number, product number, product name, and manufacturer.

Further processing>

If required, the powder coated piece may be processed further. Further processing refers to, e.g. attaching the piece with another piece by riveting, screwing, or gluing. The attached parts may be, e.g. various metal components, casters, plugs, and stickers.

Check out our other services from the following links:

Manufacturing of steel wire products-

Manufacturing of plastic products-