MANUFACTURING OF STEEL WIRE PRODUCTS

With 60 years of experience, we manufacture wire mesh, wire grids, wire baskets, wire racks, filter mesh, cable trays, safety nets, wire holders, various rod structures and other subcontracting of steel wire products.

We manufacture steel wire products on a turnkey basis. Research and development has been an important factor for our company since its foundation in 1955. For this we have our own design and tooling department. Own design, tool and product manufacturing enable you to quickly bring your new ideas to industrial production. High-quality products are guaranteed by over 60 years of professionalism, a reliable machine base and high-quality tools.

The cost-effectiveness of manufacturing steel wire products depends on the shape, size and batch size of the piece being manufactured. The product is usually designed in co-operation so that the existing machinery in our production can be utilized as efficiently as possible.

Product design

In designing products and tools, we utilize SolidWorks software, which speeds up the design process and saves time by minimizing unnecessary prototype phasis. We can provide for the customer a high-quality 3D model for review before the prototype.

Production steps

Typical work steps for steel wire products include wire straightening and cutting, wire chamfering, various welding techniques, bending and assembly welding. We use spot welding, butt welding, and MIG welding techniques.

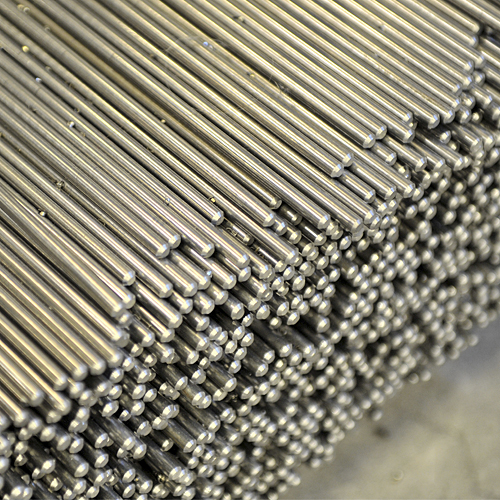

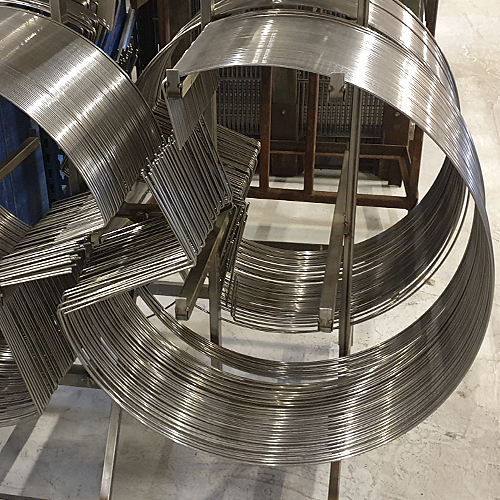

Straightening and cutting

We store steel wire in coils of some 1,000 kg and the wire is straightened and cut to measure from them. The most common wire sizes used by us have a diameter of 1.2–8.0 mm. We also keep several flat bar and pipe sizes in stock. Stainless steel wire is acquired separately according to the customer’s requirements. If necessary, we chamfer the ends of the wires.

Spot welding

We manufacture spot-welded products using automatic spot welding lines, semi-automatically or by hand in the conventional way. Our five automated spot welding lines guarantee the required capacity.

Butt welding

We manufacture different size of frames by butt welding round wire and flat wire.

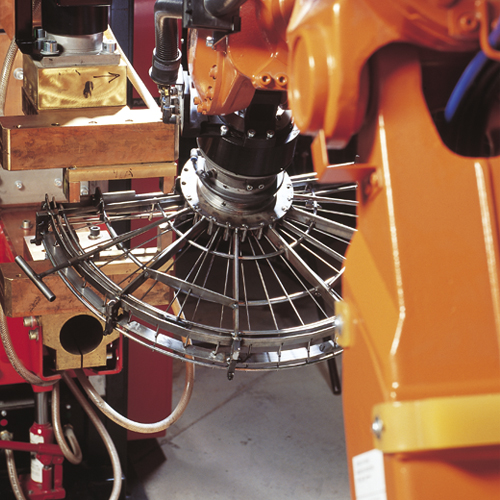

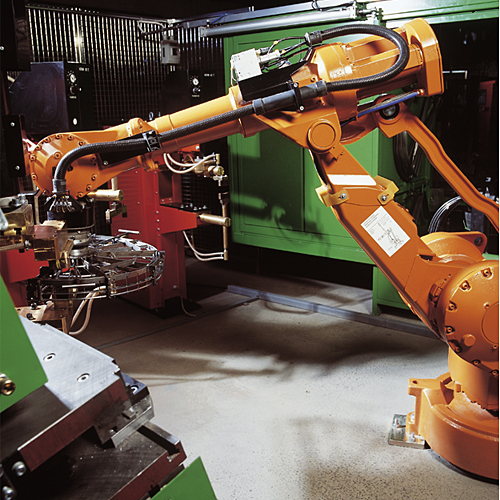

Assembly welding (MIG and spot welding)

The assembly welding of products can be carried out by robotic welding cells as well as by skilled specialists. The size of the production batch, tool weight and product requirements determine the correct manufacturing method. Steel wire, sheet metal, steel pipes and flat bars can be combined in assembly welding.

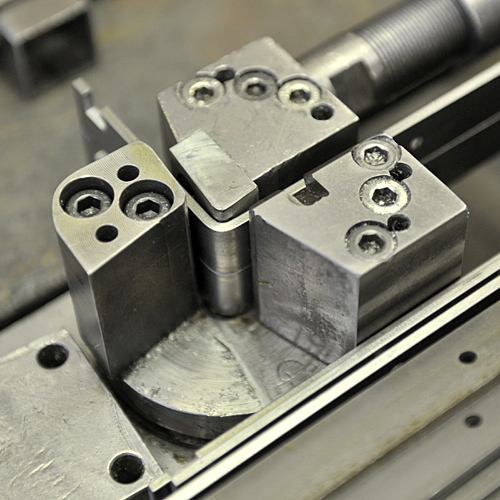

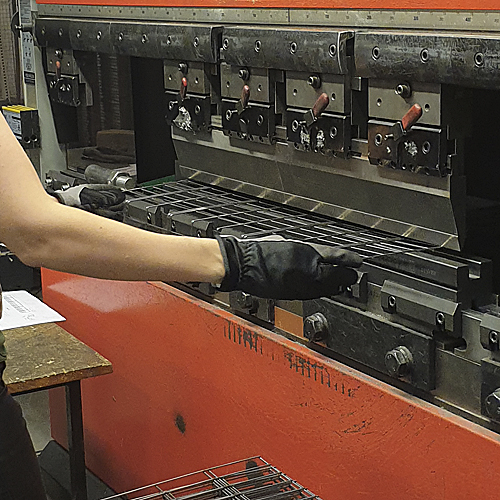

Bending

Wire bending can be done with automatic wire bending machines, which facilitate the cost-efficient manufacture of three-dimensional objects. We also perform bending using the conventional press braking machines.

Other production phases

There are several different and different sizes of presses in our production (eccentric, hydraulic and automatic) for other work stages. With press tools, we can do, for example shape bends, piercings and cuts in one step at a time or several at the same time.

Quality assurance

We comply with the ISO 9001: 2015 quality system, customized and documented agreements, and quality assurance practices. All documentation is stored in a data management system that is accessible to our employees within the scope of authority.

Product examples

We manufacture steel wire products for many industrial sectors. The limitation of design and product solutions is often just imagination. Industries include: the kitchen and furniture industry, refrigeration, shop furniture and shipbuilding, and various machine and equipment manufacturers. Products can be individual components or comprehensive product configurations. Product examples: wire mesh, wire grid, wire baskets, plate spikes, wire shelves, filter mesh, cable trays, safety nets, wire clips and various rod-like structures.

Coating options

Products can be powder coated or plastic coated in our own premises.

The manufactured products are available e.g. galvanised, chrome-plated, nickel-plated, pickled, passivated or with other special coatings. The special coatings are made by our subcontracting partners.

Good to know:

- In metal products, batches under 200 pieces are manufactured entirely manually.

- When batches vary between 200 to 500 items, we can utilize partial automation.

- Batches over 500 items we can manufacture fully automated, where the machine operator only adds raw-material in the machine.

- In steel wire product production, we use nearly 1,000 tons of steel wire per year.

- Product manufacturing from design to industrial production takes an average of about a month.