Sustainability

Made in Finland

Our products are designed and manufactured in Pori, Finland. Our entire production is located in Finland. Our products have the Key Flag mark: The Key Flag is a sign of Finnish work and can be awarded to a product that has been made in Finland.

Personnel

Lanka ja Muovi is a third generation family business that has approximately 50 employees. Many of our employees have worked with us for decades and that we are proud of.

We want to continue to develop as a Finnish employer in the coming years by setting high quality standards for our products, conducting continuous product design and investing in new technology. We also want to invest in the personnels well-being at work, e.g.by regularly conducting personnel surveys, and based on the results, develop our business so that employees' well-being is further improved.

High-quality, long-lasting products

The most important features of our products are quality and durability.The most important features of our products, apart from being made in Finland, are quality and durability.These have been the starting point for our business since the early days of our company, since 1955.

We want our products to be sustainable and last a long time with daily use.We also offer spare parts and accessories for many of our products, which means that our products have an even longer life cycle.

With the help of research and testing, we constantly develop our products to maintain even higher quality.The key role here is in-house design, tool and product manufacturing as well as continuous product development work.

Environmentally-friendly products

Along with quality and sustainability, respect for nature and natural resources are very important to us.This is reflected in the choices we make to care for our environment.The fact that our entire production is located in Pori, Finland reduces transport costs and contributes to reducing the carbon footprint.

A continuous product development work also applies to our material choices and we strive to find new, more environmentally friendly solutions: the use of recycled material and environmentally safe surface treatments are examples of this.We use a chrome powder coating on our products that does not require abrasion resistance – this is a coating with less environmental impact than traditional 3- or 6-valent chrome plating.

We also invest in product safety in our products.Most of the materials and coating options we use are approved for food use and meet the requirements of the RoHS Directive and the REACH Regulation.The exception is waste bins made from recycled material: due to the diverse sources of recycling, the material in question cannot be given a food safe certificate at the moment.

Recycled materials

Our ambition is to use recycled material in our products whenever possible. We believe it is very important that all materials are recovered and reused: in this way we reduce the need for new raw materials and save natural resources.

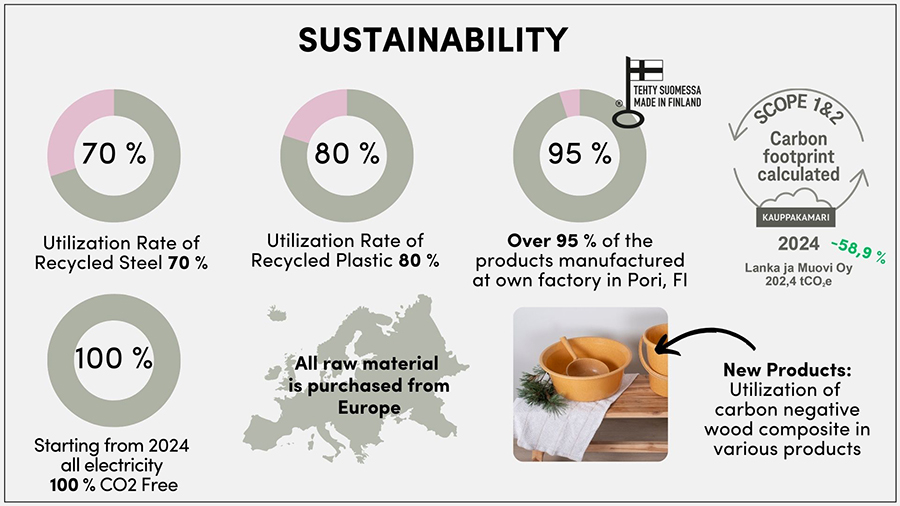

At least 70% of the steel wire we use is recycled material, and even more than 80% for plastic products. The origin of the recycled plastic used in the production of our plastic products is household plastic that has been carefully selected, cleaned and reprocessed. In addition, all plastic generated from our own process is further processed and reused as raw material for our plastic products - so we continue to use the plastic waste from our production as material for products instead of it ending up as waste.

In 2022, we launched the ECO series, and the use of recycled plastic in our products increased significantly. The series consists of containers made from 100% recycled material and lids for the containers. The ECO series has rapidly expanded and nowadays we only use new plastic in the plastic products that are food approved. We strive for a future where all our products are made from recycled materials.

Carbon footprint calculated

We have calculated the carbon footprint in the Scope 1 and Scope 2 categories.

The Scope 1 category includes emissions that the company can directly influence and that the company can most easily control. The emissions are generated on site as a result of the company's own operations.

Indirect production emissions related to purchased energy from, for example, electricity and heat production belong to the Scope 2 category.

We have managed to reduce our carbon footprint with 58,9% from the 2023 figures (492,7 tCO2e). This was significantly influenced by the transition to 100% carbon-free electricity from the beginning of 2024.

The next step is to calculate Scope 3 category emissions, which are emissions from the end use of sold products and the procurement of goods and services, i.e. all indirect emissions. These include e.g. waste management, water management, logistics, material procurement emissions.

In the future, we will also set concrete goals to reduce our carbon footprint.

Packaging material

In Germany, we have been awarded the Der Grüne Punkt certificate; this is because we want to take responsibility for all the packaging material we use.