PLASTIC INJECTION MOLDING SERVICE

Plastic products manufacturing with over 60 years of experience as a reliable subcontractor. Injection molded plastic products, design, molds and 3D printing of prototypes and short series. Ask!

Plastic products manufacturer at your service. We control the manufacturing of injection molded plastic products with over 60 years of experience. We manufacture subcontracted plastic products for companies in various industries.

Injection molding is a cost-effective manufacturing method for producing high-quality plastic products in series. Injection molding is one of the most common methods of manufacturing plastic products. Injection molded plastic parts are characterized by expensive mold cost but low unit price. For this reason, injection molding is well suited for large series production.

Design of plastic products

A properly designed and manufactured plastic part will withstand the entire life cycle of the product. We work with our customers for product development and our goal is to be involved in product design as early as possible. We can model plastic products ourselves or make use of our industrial network of industrial designers. We use SolidWorks design software to design plastic products. The latest 3D Printing Technology makes it easy and fast to manufacture prototypes, allowing you to test the functionality of your product before making a final decision on a mold investment.

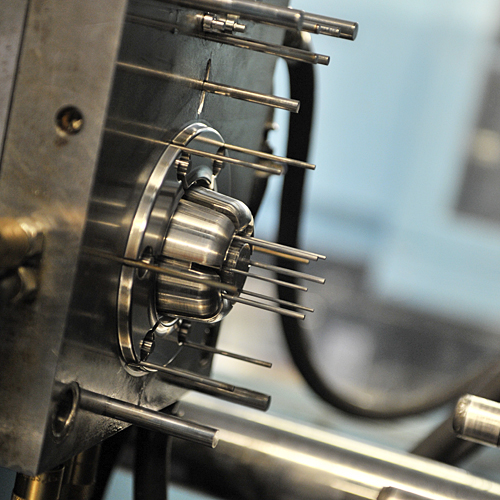

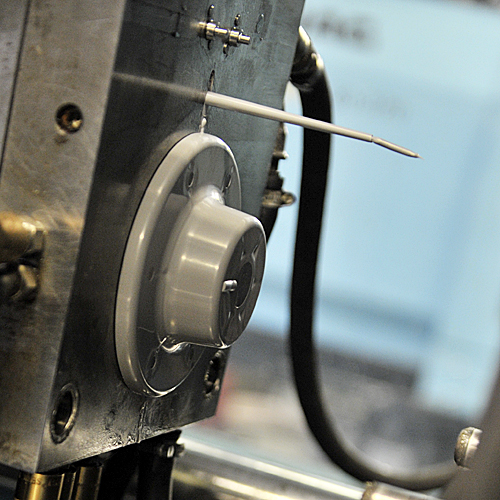

The injection molding mold is always manufactured individually, taking into account the product environment and technical requirements. The injection molding mold may be single cavity or multi cavities. Small-size volume products are usually made with a multi-cavity mold to minimize the price of the product.

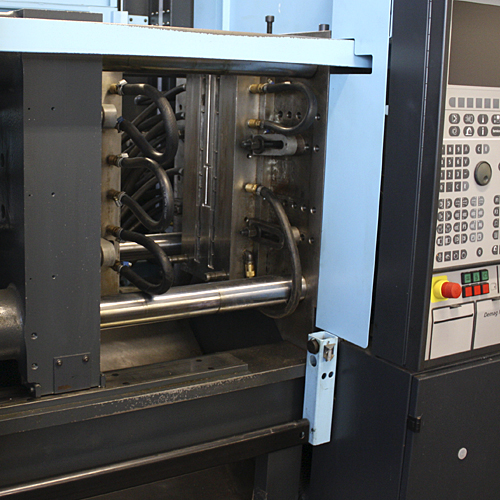

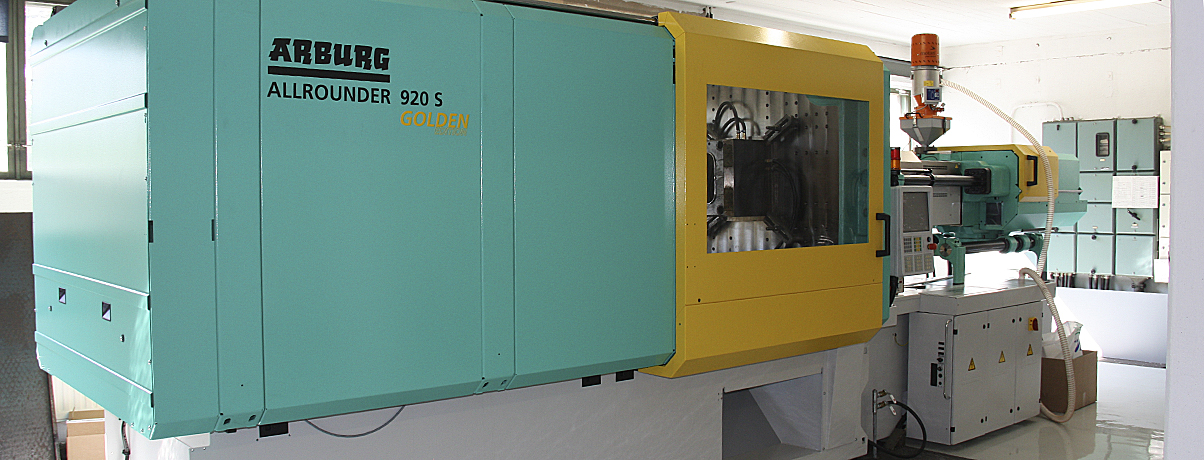

Our injection molding machines

In the manufacture of plastic products, we use the latest technology in the field and our injection molding machines represent the leading brands in the plastics industry. A reliable machine base, fast availability of spare parts and a back-up machine arrangement ensure consistent quality of production and products. Our smallest injection molding machine has a clamping force of 45 t, the largest 460 t. The level of equipment for injection molding machines enables competitive small series as well as volume production.

Raw materials

The desired properties of the product define the type of plastic used for the manufacture. The choice of plastic grade is influenced by several factors, such as the product's operating temperature, mechanical or chemical stress on the product. Our stock of raw materials is available in a variety of plastic grades such as: LDPE, HDPE, PA, PP, PC, ABS, HIPS. If necessary, we can utilize the expertise of our raw material suppliers in choosing the plastic grade of the product being offered. Our standard colors are white, light grey, anthracite grey, yellow, red, black, brown, blue and green. Also ask for product availability with your own RAL color number. If there is no known RAL number, we can analyze the desired color in the laboratory according to the sample part. All of our stock raw materials meet the product requirements for food use.

Value-added services

We can provide the assemblies of the product to be manufactured from a number of different plastic or steel parts. The product to be manufactured is packaged and labeled according to the customer's wishes. We can attach a label to the product or add an instruction manual to the packaging. Finished product collars are provided with a collar, which includes e.g. manufacturing date, batch number and employee initials. The delivery may be accompanied by certificates of the raw materials used and of the batch-specific raw material tests.

Quality assurance

In our company, we adhere to the quality system according to ISO 9001: 2015, customized and documented agreements and quality assurance practices. All documentation is stored in a data management system that is accessible to our employees within the scope of authority. Our company 's over 60 years of history and satisfied customers are guaranteed by the high quality of our products, professional staff and continuous development of our expertise and production automation and technology.